Our approach

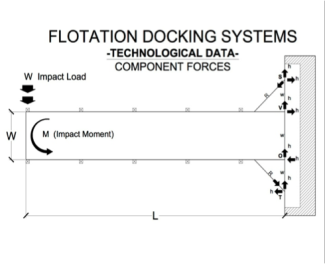

Having developed our products over a span of nearly fifty years in a northern freshwater environment, our engineering methodology remains among the highest quality and most enduring within the industry. Throughout this time, we’ve maintained a core set of design fundamentals and rigid quality control process that directly mirror performance specifications of the Michigan Department of Natural Resources and Michigan State Waterways Commission.

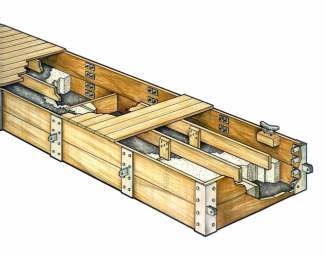

Additional detail regarding our unique product design is provided below, and general product specifications as well as our brochure can be viewed / downloaded immediately following this section.